Blog

Flow hives: high technology in apiaries

Many people think of beekeeping, bees and their hives as a very simple and primitive activity, using the same technology and nothing has changed for hundreds of years. Although the most basic beekeeping has remained unchanged for quite a long time, we are constantly striving for better results, which is why we are continuously introducing appropriate technologies.

Bottomless hives were the start of innovation

From the very beginning of Brothers' Honey, brothers Ignas and Vilius Jackevičius have been making all the hives themselves in Kupiškis. Almost nothing has changed, except that instead of the simplest hives, made from materials that are "just around the corner", we now use special bottomless hives - we now have more than 90 colonies of bees, and we strive to provide them with the best conditions.

We keep our bees in an organic and completely natural environment, so they are constantly surrounded by forests and meadows. As a reminder, our apiary is part of an exceptional quality programme - our hives are regularly inspected and the certificate we have been awarded only proves once again that our honey products are of high quality.

Bottomless hives, as the name suggests, do not have a bottom, but only a metal net to protect the bees from insects and wild animals. The narrow bottom allows air to circulate in the hive continuously and in all seasons. This ensures even better health and well-being for the bees and, of course, higher quality honey.

Flow hives - the latest innovation in apiaries

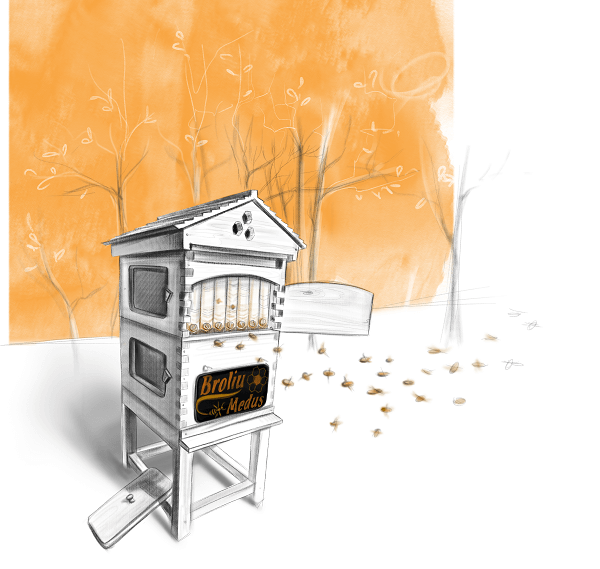

This year, Brolių medaus apiary has introduced a new generation of flow hives, which we only learned about in autumn last year, when this type of hive was introduced. So we decided to contact the hive engineers in Australia, and six months later, the first of these hives arrived in our country. Of course, we had to make some modifications to the hive to adapt its design to our climate: we have insulated the walls of the hive, thickened them a little, installed a hollow bottom to allow ventilation at all times of the year, and installed a large number of glass windows to allow sunlight to penetrate into the hive, which also gives us the possibility of being able to see the entire life of the bees.

It took the bees about two weeks to get used to the new combs, which are made of plastic instead of the usual beeswax, so it was a serious challenge for the bees and for us. However, it was well worth the wait and the work, as we already saw the first results at the end of spring. Thanks to the smart combs, all the bees have to do is to bring the honey into the combs. Well, all we have to do is insert a special key and then the honey starts flowing through the tap directly into the container or spoon, so there is no need to dig, swirl, etc.

Even the Japanese Ambassador came to see this innovative hive - in Japan, natural Lithuanian honey is becoming more and more interesting to the public because of its unique taste and healing properties. Although this type of hive is not yet intended for industrial beekeeping, we still use it - it's like our representative product, and we also use it to educate the public about the life of bees - after all, you can see all the bees through the hive's windows!